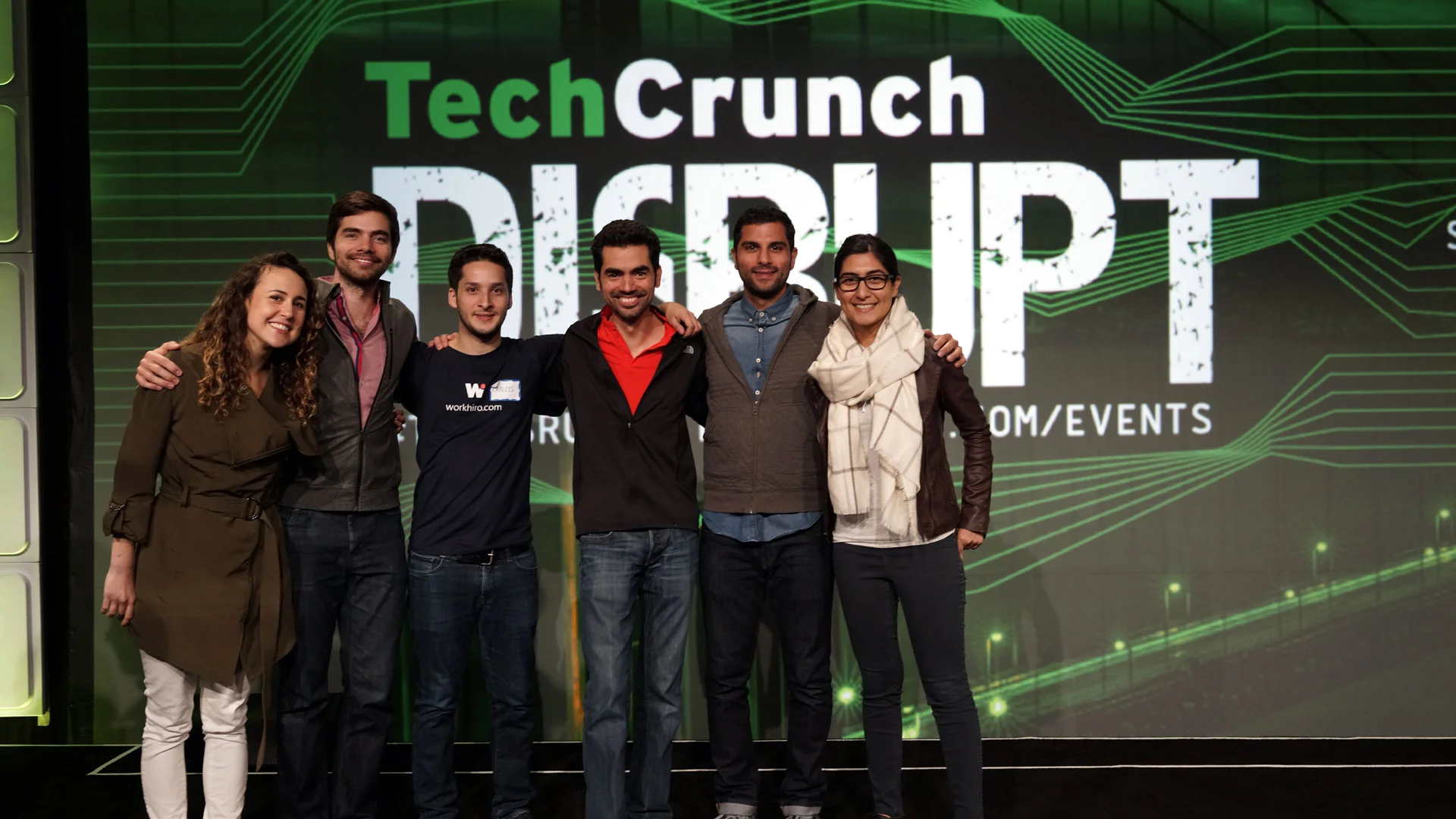

Winner of the TechCrunch Disrupt SF Hackathon

Winner of the TechCrunch Disrupt SF Hackathon - US Department of Commerce sponsored hack. Awarded to the team who creates a product with a viable business model that helps homes become smarter and more efficient.

Here with our friends from the U.S. Department of Commerce.

Our CEO, Jesus Treviño being interviewed at midnight. Interview at the ~1:10 min.

Live announcement of the TechCrunch Hackathon winners- our mention comes in at ~14:30 min

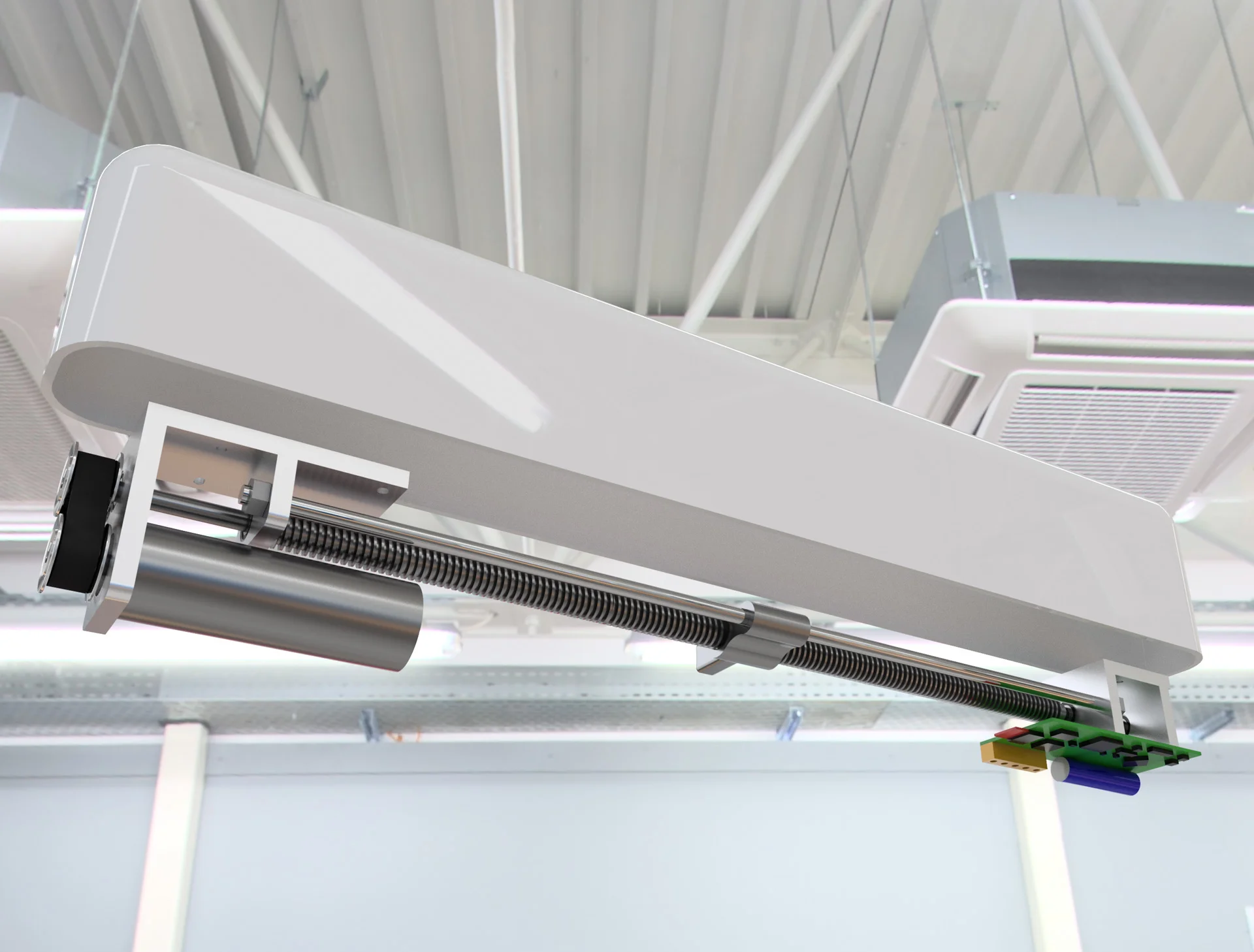

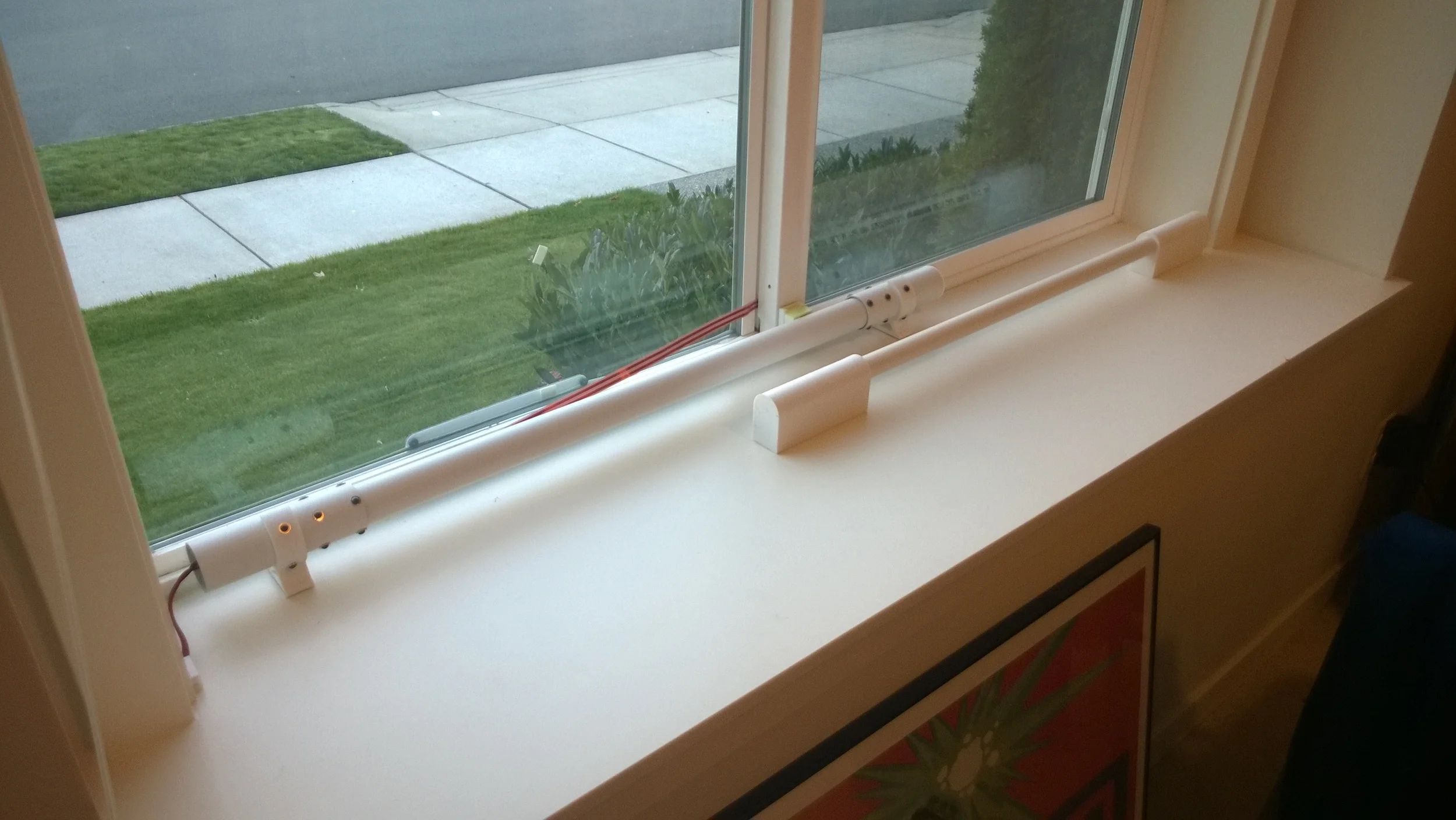

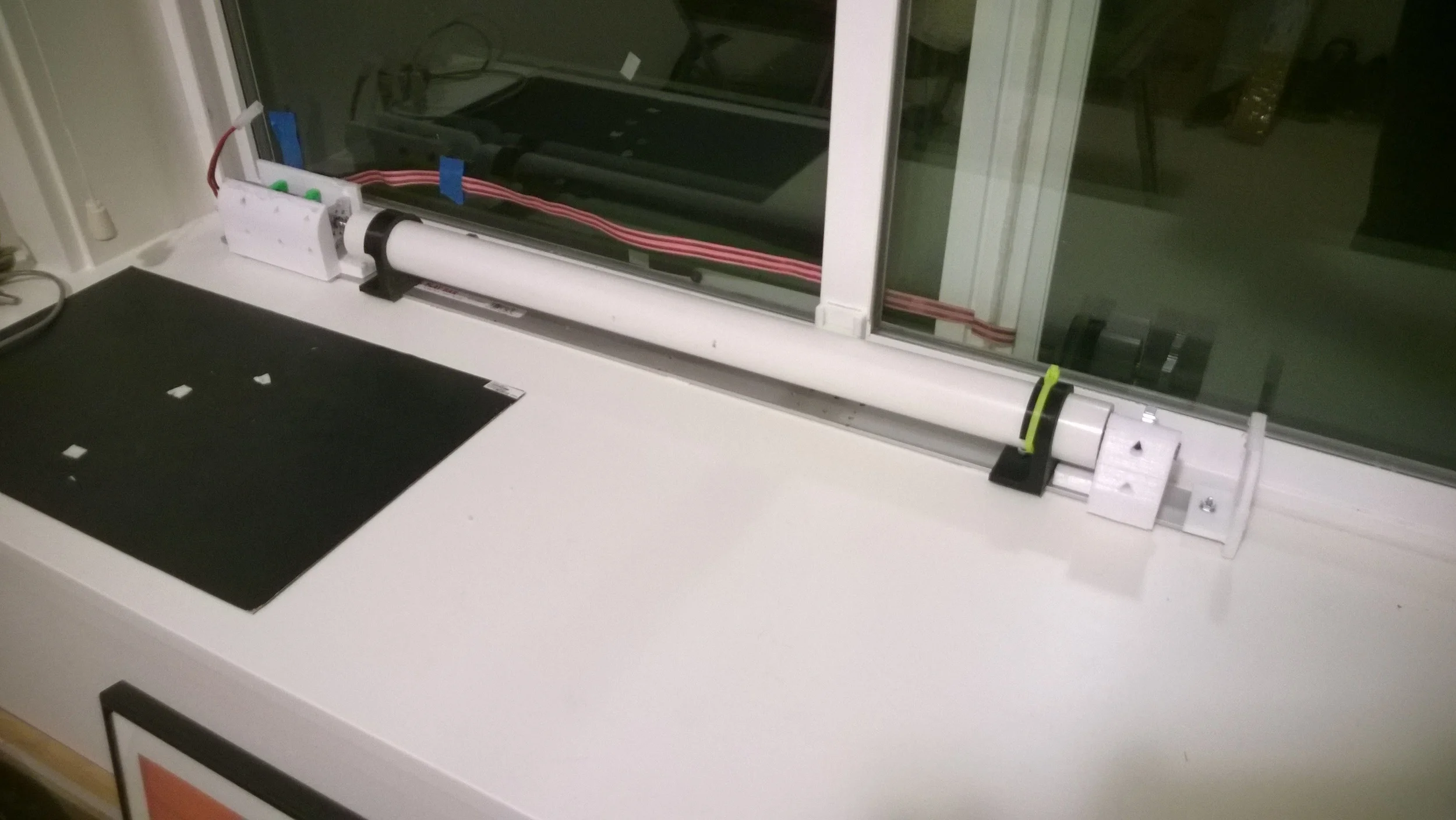

For more info about our hack visit the NIST Net-Zero Facility website or read our white paper.